| Measurement GuideHow to measure for straight tracks

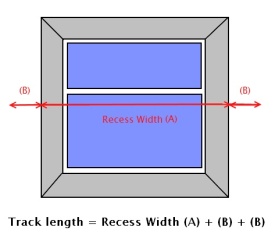

To calculate the overall length of track or pole required: i) measure the inside recess width in centimetres (A) and ii) add a minimum of 15cm (B) to either side i.e. add at least an additional 30cm (15cm *2) to the inside recess measurement. The total track length required is A + B + B. How to measure for tracks with finialsPlease be aware that the above measurement is for the track length only, should you wish to have finials at either end of your pole you will need to allow enough space to add on the length of each finial (note two finials in total) to the overall length of the pole. WHEN ORDERING PLEASE PROVIDE YOUR EXACT POLE LENGTH EXCLUDING FINIALS BUT REMEMBER TO ENSURE YOU HAVE ENOUGH SPACE FOR THE FINIALS WHEN INSTALLING THE POLE To minimise mistakes when measuring we would strongly advise that measurements be taken in centimetres using a metal tape measure. How to measure for bent tracks to fit bay or curved windowsWith the exception of the 50mm system 6150M (electric operation) all tracks can be bent to varying degrees depending on the recommended minimum bend radius*. Should your chosen track require bending to fit a curved or bay window please indicate on order. Once we have received of your order we will make contact to assist with calculating accurate angles and measurements to ensure your bent track will fit perfectly. For the further information on how to measure for bent tracks please use the link below to view the Silent Gliss angle measure guide /user/Silent_Gliss_Angle-measure.pdf. The following information provides minimum bending radius for our products: Electric Tracks

Metropole Range

* Bend radius is the minimum a track or pole can be bent without kinking, flattening the profile or causing a problem with functionality. Generally speaking as the bend radius decreases the curvature increases. Contact usShould you have any queries or questions about measuring for tracks please feel free to contact us by email or call 029 2036 1933.

|

wording 192 new.jpg)